Products | Driver Safety

Protect your fleet and profits with an all-in-one safety solution.

New report: We surveyed 1,000 physical operations leaders. 59% say rising costs are their biggest threat. Will AI save the day? Explore the findings.

How it works

Use the power of AI to enhance fleet safety.

Proactively manage safety

Get time back

Deliver documented results

Proactively manage safety

Maximize fleet safety and minimize risk with Motive’s AI-powered platform. Protect your business with accurate, real-time driver coaching and accident detection, on-the-spot exoneration evidence, and privacy protection.

Reliable AI

Collision detection

Video recall

AI Omnicam

Privacy Mode

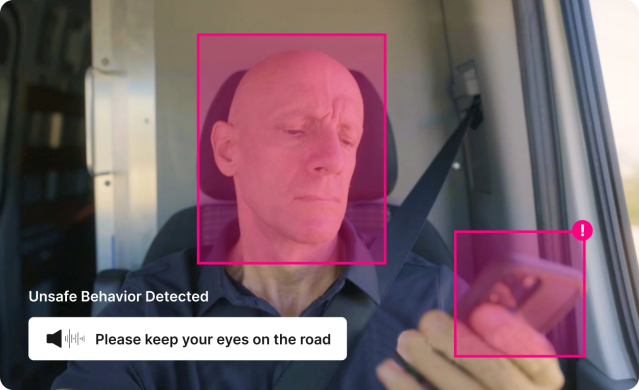

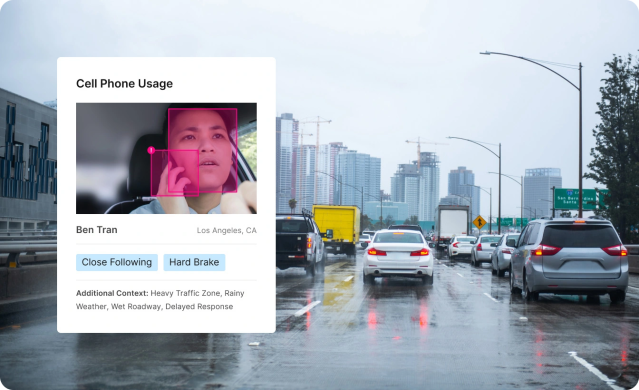

Reliable AI

The Motive AI Dashcam is the most accurate, fastest AI dash cam in the industry. Motive’s AI detects unsafe behaviors like cell phone use and close following with fewer false positives than competitors, alerting drivers in real time. That means fewer accidents and happier drivers.

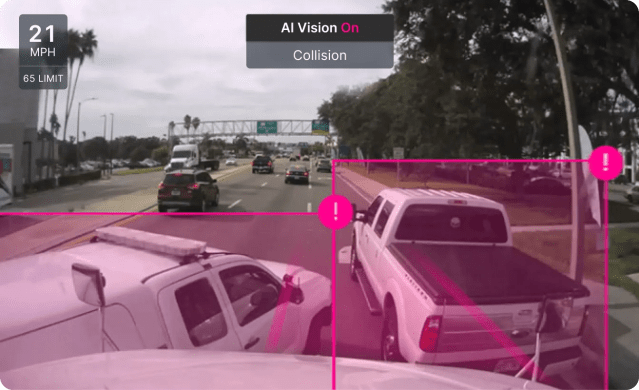

Collision detection

Motive leads the industry in accident detection, enabling you to take immediate action. We automatically detect 99% of severe accidents and upload footage within seconds, minimizing risk of losing footage.

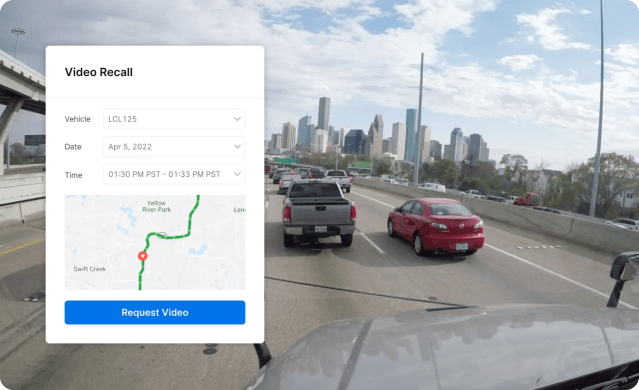

Video recall

Access dash cam footage from the last 30 to 235 hours to see exactly what happened. Get up to 60 minutes of HD footage with every request. Admins can choose to record video even when the engine is off to protect drivers around the clock.

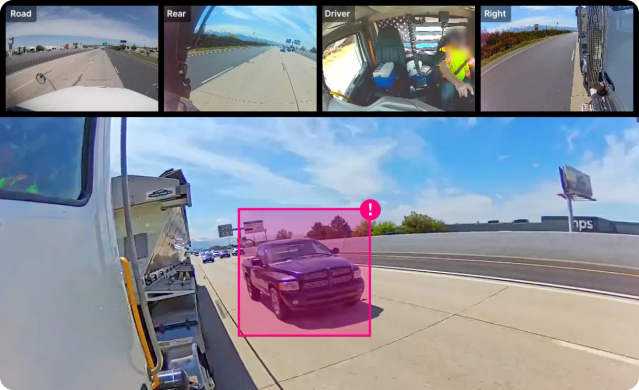

AI Omnicam

Regain time and control with a 360° view of each fleet vehicle. The AI Omnicam provides comprehensive side, rear, passenger, and cargo monitoring. Reduce accident costs, manual incident reviews, and safety checks.

Privacy Mode

Motive helps protect driver privacy by providing the option to disable the driver-facing camera while drivers are off duty or when the engine is idling. Admins can activate Driver Privacy Mode for the entire company, a group, or an individual driver.

Get time back

Manage driver safety with Motive’s all-in-one platform and reduce your safety department’s workload through automation. Eliminate repetitive, or time-consuming tasks with self-coaching tools, prioritized footage, and custom safety definitions.

Motive Safety Team

Event severity

Coaching sessions

Driver App

Motive Safety Team

The Motive Safety Team reviews all safety events and removes false positives so that you can save time and focus on the safety events that really matter. The team also reviews all collisions within seconds to ensure validity.

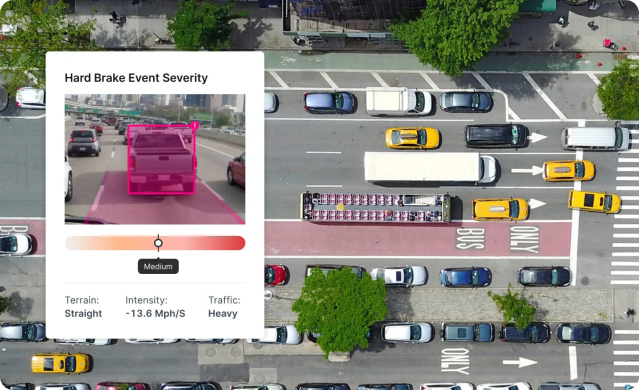

Event severity

Every dash cam video is assigned a severity level based on a variety of factors including, the place, time of day, road conditions, traffic level, and other insights. Motive surfaces only the most important videos for safety departments to review, saving your team countless hours. Learn more

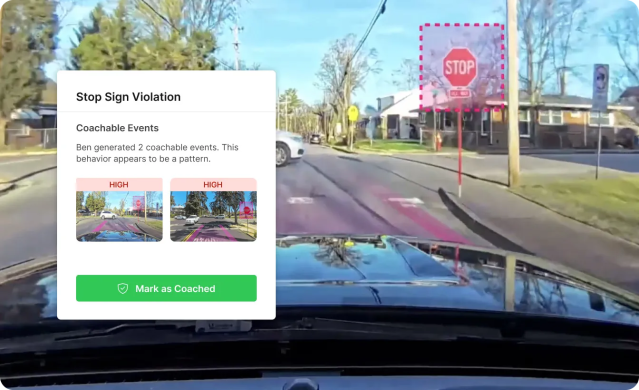

Coaching sessions

Motive’s turnkey coaching workflow automatically pinpoints drivers and behaviors that require attention. All relevant videos, speeding events, and coaching history are surfaced in one view to help managers provide personalized, timely feedback. Easily identify unsafe driving patterns and get full safety context on every video.

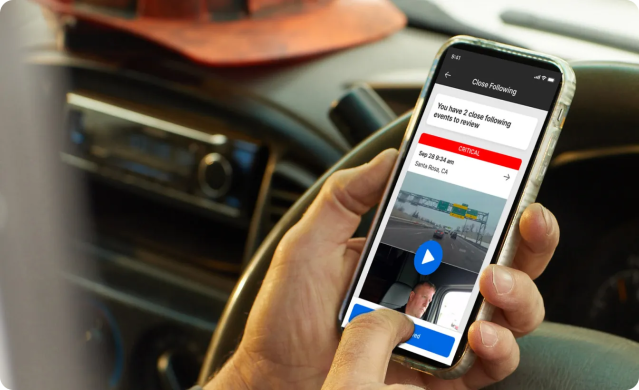

Driver App

Drivers can view dash cam videos at the end of a trip in the Motive Driver App. With coaching delivered immediately after a safety event, drivers are more likely to remember the context and correct the behavior. Admins can disable dash cam video access in the Driver App if they prefer to coach in the office. Download for Android and iOS.

Deliver documented results

Show improvement in safety and differentiate your business with Motive’s advanced risk scoring and reporting. Earn more business and improve profitability with more accurate accident prediction, actionable coaching reports, and safe driver recognition.

Safety Score

Safety Hub

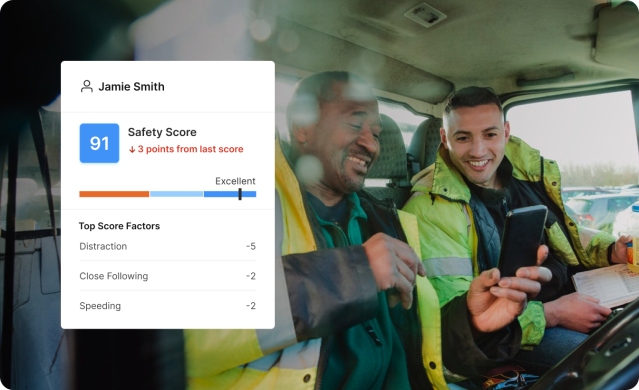

Safety Score

The Safety Score evaluates driver safety performance over time to provide an accurate measure of driver risk. Safety Score is 5x more accurate at predicting accidents than the industry benchmark. Easily pinpoint who you should be coaching or rewarding and what behaviors to focus on. Learn more

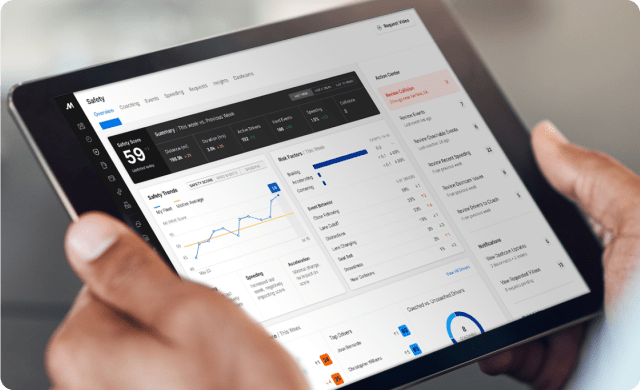

Safety Hub

Manage your safety program in one place for full visibility into driver safety with the Safety Hub. Identify your riskiest drivers and take the actions necessary to prevent accidents.

A fleet safety solution that gets results.

Motive technology by the numbers:

57%

30%

21%

10x

Prevent accidents

Coach drivers

Cut costs

Exonerate drivers

Powering the businesses that keep the economy moving.

Related resources

Benchmark report

Motive achieves highest alert rates for six unsafe behaviors.

NEW study by Virginia Tech Transportation Institute reveals Motive’s AI Dashcam successfully alerts drivers to unsafe driving behavior 86% of the time, 3-4x more than the latest models from Samsara and Lytx.

Most accurate AI

Driver coaching

Safety program

Frequently asked questions

What types of fleet driver safety events trigger video recordings?

Recordings are triggered by unsafe driving behaviors such as close following, cell phone use, and hard braking. Other triggers include hard cornering, hard accelerations, and seat belt violations. This list will grow as we continue to train AI detection models for our fleet safety software.

Does Motive’s AI Dashcam require additional data usage on a smartphone?

No. The AI Dashcam uses cellular connectivity in the Vehicle Gateway to upload all triggered video content.

Do I need a mobile DVR system with AI Omnicam?

No, you do not need any DVR. AI Omnicam has built-in LTE connectivity to directly communicate with the Motive cloud network. The only wired connection AI Omnicam needs is for power to either 12V or 24V power source.

Does the AI Dashcam record the driver?

We offer road-facing and dual-facing dash cams, depending on your fleet safety needs. The road-facing dash cam only has one camera that records what’s on the road. The dual-facing dash cam has both a road-facing and driver-facing camera that records in the cab. Administrators can activate Driver Privacy Mode to disable the driver-facing camera for select drivers. Customers can purchase either camera, depending on which type of fleet safety system they prefer.

How does live streaming work?

Managers can view live dash cam video to train drivers remotely and recognize them for safe driving. This optional feature was built with driver privacy in mind. To use, it must be turned on by a fleet administrator. In-cab audio and visual alerts notify drivers when the live stream starts and ends. These alerts can’t be turned off. Only users with live streaming permissions can initiate this feature.

What are the benefits of fleet safety program?

A well-designed fleet safety program brings numerous benefits, including reduced accidents, lower associated costs, improved driver morale, enhanced public safety, and compliance with regulatory standards. Additionally, it can lead to lower insurance premiums, increased operational efficiency, and a positive impact on a company’s reputation.

How can fleet safety be improved?

To improve fleet safety, organizations can implement comprehensive driver coaching programs, regularly maintain and inspect vehicles, utilize advanced safety technologies such as AI Dashcams and AI Omnicams, and establish clear safety policies and procedures. Encouraging a safety-conscious culture within the organization and fostering open communication about safety concerns are also crucial.

How do you create a fleet safety program?

Creating a fleet safety program involves several key steps. First, assess the unique risks and challenges associated with your specific fleet operations. Develop clear and comprehensive safety policies and procedures, including guidelines for driver behavior, vehicle maintenance, and emergency response. Learn more in our step-by-step guide.

What are the key elements of an effective safety program?

Key elements of an effective safety program include leadership & employee commitment, comprehensive training, ongoing communication, and a robust monitoring and evaluation system. Incentivising & rewarding good safety behavior and performance, regular assessments and open communication channels contribute to continuous improvement, creating a safer and more efficient fleet environment.

How Do You Measure the Success of a Fleet Safety Program?

Success in a fleet safety program is gauged by reduced accidents, lower costs, and improved driver behavior. Adherence to policies, successful completion of safety training, and the utilization of advanced safety technologies such as AI dashcams contribute to the achievement of safety program goals. Use the Motive Safety Score and Coaching Sessions for regular driver reviews to ensure ongoing improvement.

Get started today