Most industries can benefit from GPS tracking, but the positive results and return on investment are quickly apparent in construction. Using GPS tracking technology, construction companies can run more efficiently and improve profitability with the ability to track and locate assets in real time. This article explains how GPS construction equipment is used and further explores the advantages of GPS fleet tracking for this industry.

How is GPS tracking used for construction equipment?

GPS tracking software relies on the Global Positioning System developed by the military to track and determine the location of assets. Today, any company can use GPS tracking devices that send a signal to satellites which then bounce a signal back to help the transmitter calculate location.

Top-rated construction GPS equipment is installed in or on heavy-duty vehicles and other equipment to track and transmit the asset’s whereabouts. This offers many benefits, which we’ll discuss in more detail next.

Why use GPS in the construction industry?

Using GPS technology in construction has numerous advantages, including theft deterrence, time savings, and safety.

Read: What is GPS fleet tracking technology?

Locate missing or stolen equipment

Nearly 1,000 pieces of construction equipment are reported stolen each month to the National Crime Information Center (NCIC). Thieves target backhoes, loaders, bulldozers, forklifts, generators, and other valuable assets because of their high resale value.

This theft is costly. Not only does the company face the hard cost of replacing the stolen equipment, but insurance costs can go up too. In addition, theft can cause project-stopping delays, which could mean missed deadlines and even the loss of a customer.

Heavy equipment tracking can help superintendents monitor assets in real time. And a GPS tracker may discourage bad behavior. Warning signs alerting would-be thieves that the equipment is equipped with GPS tracking devices may be a great deterrent. Tracking devices may also help recover stolen equipment.

Streamline workflow and asset allocation

Downtime costs money. In the days of paper-based records, an asset inevitably sat idle in between assignments. Even if we’re only talking about an hour, multiply that amount of time by the number of pieces of equipment your business owns. Then add the number of jobs you take on over the course of a year, and you’ll start seeing potentially large financial losses.

Equipment also experiences costly downtime when sent to the wrong job or to a job where it isn’t needed. Whether an asset is simply waiting for its turn to be sent on a job, or your staff is losing valuable time looking for it, when it’s not on the job, it’s not making you money.

Construction GPS tracking allows your fleet to know an asset is becoming available before it happens, so you can make the best use of it with the shortest amount of transition time. At the same time, since you can track all of your assets in real time, you always have a complete picture of what your needs are on every job site.

Prevent misuse of vehicles and equipment

Sometimes employees use work trucks or other company vehicles for personal reasons. Personal use of company equipment increases your liability and can result in increased insurance premiums if an incident should occur.

If personal use is against company policy, GPS tracking for construction equipment will tell you where and when unauthorized use occurs.

Improve safety

GPS tracking devices can play a large role in helping companies monitor the driving habits of their workers. Devices can provide reports and notifications chronicling the speed at which the vehicle is moving. This includes whether it has accelerated beyond the posted limit. It also includes if the vehicle has been subjected to aggressive driving like hard turns or stops. These can be indicators of close calls.

A good overall fleet management solution can tell you when to coach your drivers and help them improve their skills. Our AI-powered safety platform combines real-time in-cab alerting, automated post-trip coaching, and predictive insights from the DRIVE risk score to help reduce accidents by up to 30%.

Safety depends just as much on vehicle health as on driver skill. Overusing assets and falling behind on regular maintenance are two risk factors for maintenance issues.

Equipment can break down after sustained use, especially if the contractor has a full schedule and backlog of projects. If breakdowns occur and repairs can’t be made on site, new equipment is brought in as a replacement.

Streamline your construction fleet management strategy

While it may not happen often, there are instances when crews aren’t on the job site when they should be. GPS tracking can give you a real-time map of your vehicles, drivers, and all of the assets related to that specific job. This lets you know exactly where they are at any given time.

GPS tracking can also assist you in tracking the hours worked for your crew, which helps when billing customers. You can use the GPS to track your crew’s labor hours based on their arrival time on site.

With real-time data insights into assets, operational efficiency improves. This can help the construction company sidestep delays, reduce costs, and avoid unforeseen expenses. Cutting downtime and increasing accountability may help the company improve client relationships too.

The case for GPS construction tracking

Cordy Environmental Inc. used the Motive Vehicle Gateway to exonerate its driver when there was an issue onsite. The customer thought Cordy’s driver dumped drilling mud somewhere it wasn’t meant to be. Allen Chatten, the company’s HSE Advisor, was able to open up GPS location history and prove it wasn’t their drivers. “We were able to exonerate ourselves because we proved that we had never even been there in the last two weeks,” Chatten said. “That was a big help for us because we kept our good standing with our customers.”

Why use Motive’s GPS construction tracking?

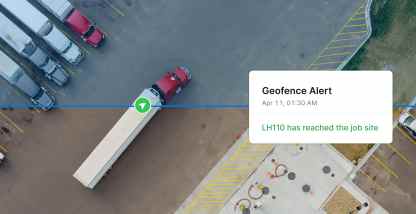

Motive’s real-time fleet tracking software for the construction industry takes the guesswork out of knowing where your drivers, vehicles, equipment, and trailers are at any time while protecting your valuable assets. Superintendents can even set up geofencing alerts to simplify dispatch or know immediately if heavy equipment is being taken outside of the allowed boundaries.

Learn more about how Motive can help your business and keep your construction industry customers happy. Request a demo today.