This comprehensive guide covers the definition of flatbed hauling, its benefits, shipping tips, and other crucial things you need to know about hauling cargo using a flatbed.

Let’s start with what a flatbed truck is and its types and uses.

What is a flatbed truck?

Flatbed trucks are large vehicles with flat bodies. They don’t have roofs or sides.

The vehicle’s unique bed design is ideal for loads that are too wide for trucks with enclosed bodies.

Because forklifts can be maneuvered from any side of the vehicle, a flatbed’s design structure simplifies the loading and unloading of cargo.

Are there different types of flatbed trailers?

If you want to become an owner-operator or start a trucking company with a fleet of trucks, knowing the different types of flatbed trailers and their uses is essential.

Here are flatbed trailer types that could be part of your fleet.

1. Step deck

A step deck, or drop deck, is a flatbed trailer with a top and bottom deck. The step deck is commonly used for cargo that is too wide or tall to fit into a standard flatbed.

Step deck loads usually ride lower in the trailer. Being lower allows the vehicle to pass under low bridges, even with tall loads. At ground level, you can use loading ramps to get on and off the bed easily.

2. Extendable flatbeds

Extendable flatbeds, or flatbed stretch trailers, transport cargo that is too long to fit onto a standard flatbed.

An extendable flatbed truck can haul freight without overhang. However, larger loads may require a permit and escort vehicles at times.

3. Stretch single-drop deck

This trailer type is similar to extendable flatbeds. But it comes with a drop deck.

The vehicle can lengthen its bed like an extendable flatbed. It can stretch to accommodate cargo that is too long for standard step decks. Essentially, a stretch single-drop deck can legally carry loads that standard drop-deck flatbeds can’t.

To secure large cargo, you can attach a bulkhead to the trailer’s front. This can protect the freight from coming loose during hard-braking events.

Attaching a bulkhead should also allow the cargo to bend and go over the truck’s cab. Instead of into it.

4. Double drop

Double-drop flatbeds allow you to load oversize freight, including items more than 10 feet tall.

Besides a front and back deck, double-drop flatbeds have a well in the middle. The well is usually 25 to 29 feet long to accommodate tall freight.

But the well can shorten your space for loading cargo. It requires a crane and other flatbed trucking tools to load and unload.

5. Removable gooseneck trailer (RGN)

RGNs are versatile trailers you can use for long and tall loads, such as large machinery. RGNs are detachable. The trailer can be dropped to the ground to become a ramp. That means you can drive heavy equipment right onto the deck.

RGNs are usually designed with three to 20 axles. Axles allow them to carry and deliver heavy and massive payloads.

6. Side-kit

Side-kit flatbed trailers include panels, curved metal spines shaped like bows, and stakes around the bed’s perimeter. Together they provide a structure that allows you to attach tarps if needed.

When tarps are attached, the side-kit flatbed’s design can protect sensitive cargo from exposure to the elements.

7. Lowboys

A lowboy trailer can handle cargo that is too tall for step deck flatbeds. Lowboys resemble step decks. These vehicle types include a double drop. They sit lower than standard drop deck trailers.

Lowboy trailers sit 18 inches off the ground. Their height allows them to accommodate freight that requires clearance heights of up to 11 feet and 6 inches.

Flatbed hauling: Legal dimensions you need to know

The points below cover commercial flatbed trailer types and their corresponding dimensions and weight capacity.

Standard flatbed trailer dimensions

The general rule requires that the total weight of the truck, cargo, and trailer not exceed 80,000 pounds.

For standard flatbeds, the maximum freight dimensions are outlined below.

- Length: 48 feet to 53 feet

- Height: 8.5 feet

- Width: 8.5 feet

The maximum freight weight must be 48,000 to 52,000 pounds.

Step deck

The step deck’s legal weight and dimensions are described below.

- Maximum freight weight: 48,000 pounds

- Top deck length: 11 feet

- Bottom deck length: 37 feet

- Width: 8 feet 6 inches

- Bottom deck height: 10 feet

Extendable flatbeds

The maximum legal weight and dimensions for extendable flatbeds are outlined below.

- Maximum freight weight: 43,000 pounds

- Minimum length: 48 feet

- Maximum length: 80 feet

- Height: 8 feet 6 inches

- Width: 8 feet 6 inches

Double drop

The legal weight and dimensions for double-drop flatbeds are outlined below.

- Maximum freight weight: 36,000 to 42,000 pounds

Main deck

- Length: 25 feet to 29 feet

- Width: 8 feet 6 inches

- Height: 11 feet 6 inches

Front deck

- Length: 10 feet

- Width: 8 feet 6 inches

- Height: 8 feet 6 inches

Rear deck

- Length: 9 feet

- Width: 8 feet 6 inches

- Height: 10 feet

Side-kit

The legal flatbed dimensions and weight limits for side kits are outlined below.

- Maximum freight weight: 45,000 pounds

- Length: 48 or 53 feet

- Width: 8 feet 4 inches

- Height: 8 feet 6 inches

What are oversized flatbed dimensions?

Flatbed dimensions exceeding 8.5 feet wide are considered oversized.

Shipments that exceed 12 feet in width might require one or two pilot vehicles of the flatbed vehicle.

Also, weight restrictions are applied on a per-axle basis. That means shipments can’t exceed the total weight limit but might exceed the per axle value.

In such cases, adjusting the load can make your shipment legal, eliminating the need for special requirements and permits.

How to ensure flatbed loads are safe for hauling

Safety protocols, standard processes, and trucking essentials are critical to keeping flatbed loads safe.

Follow the tips below to ensure a secure flatbed load and safe flatbed driving.

1. Use the right tie-down equipment and plan the cargo placement

After loading and distributing the cargo load safely and evenly, determine the number of tie-downs required and where each should go.

According to the Federal Motor Carrier Safety Administration (FMCSA) cargo securement rules, you’ll need at least one tie-down for every 10 feet of cargo, and any fraction beyond that.

For example, a 35-foot long flatbed freight would require four tie-downs.

You should also factor in the total working load limit of the securement devices, chains, and tie-down straps. The load limit should be 50% of the total cargo weight.

You can check the limits on the manufacturer manuals or its visible tags.

Keep these quick tips in mind when selecting securement devices.

- Ensure the chains, chain binders, and ratchet straps can keep your freight fastened tightly in place when the rig is moving

- Opt for cargo straps made of softer materials, such as plastic piping and lumber, to avoid potential damage

- Invest in corner and edge protectors to extend the lifespan of your tie-down straps

- Conduct fleet safety training and coaching for your drivers and staff to make sure everyone knows the proper equipment and ways to set them up

It’s always good practice for drivers to do quick inspections every 50 miles. The inspections ensure that cargo hasn’t shifted and that tie-downs are still holding.

2. Double-check your specs and distribute the cargo evenly

Avoid exceeding your flatbed trailer’s standard maximum freight weight. Distribute the cargo evenly to prevent the flatbed trailer from tipping or swerving.

Follow these general best practices.

- Calculate the freight weight to distribute it properly and secure the cargo

- Start stacking the load in the middle and move outward

- Place heavier items above the axles and lower to the deck to keep a low center of gravity

- Position 60% of the load in the flatbed trailer’s front half to keep the back end lighter and less unwieldy during transit

3. Take proper precautions

Flatbed trucking drivers must exercise caution when loading, securing, unloading, and transporting cargo. To avoid accidents and life-threatening injuries, drivers should also be careful when working on or around trailers.

Follow these safety tips.

- Provide appropriate gear, such as ankle supports and non-slip footwear

- Make sure everyone is mindful of obstructed walkways and narrow ledges that could cause anyone to fall or lose their footing

- Ensure your personnel follows standard procedure when loading, securing, moving, and unloading flatbed cargo

- No one should jump from the trailer, and anyone going down must use the steps and climb down carefully

- Use a fleet safety solution that allows you to track dangerous flatbed trucking driving behavior

Benefits of flatbed shipping for freight companies

Flatbed shipping can be one of the most effective and secure ways to transport and handle cargo. Below are four benefits of flatbed shipping.

1. Flexibility

A flatbed truck’s design allows cranes and forklifts to load goods from all angles. This makes loading, transporting, and unloading heavy and massive cargo easier.

It’s especially useful for hauling heavy machinery and equipment for the construction industry.

2. Allows you to optimize trips

Flatbed trucks can transport high volumes of materials in one trip, saving you time and money.

Flatbed hauling also lets you transport oddly shaped cargo easily. That means you don’t need to break the item into parts to move it.

3. No loading dock restrictions

There are no loading dock restrictions for flatbed hauling, helping to expand your service coverage.

Flatbed trucks can deliver goods to any location, including residential neighborhoods and large construction sites.

4. Secure cargo

Since the freight is exposed, flatbed trucks have specific standards to secure cargo.

That means you’ll need to take more precautions. To keep the cargo from shifting during transport, you’ll also have to use heavy-duty equipment, such as chains, tarps, and coil racks.

Flatbed shipping helps keep cargo safer and more secure. It ensures that everything arrives at the destination unscathed.

Flatbed shipping tips

Follow the tips below for proper and efficient flatbed shipping.

- Understand the freight details. Know the type of cargo you’re hauling to determine the right materials to secure the flatbed freight during shipment. Also know the cargo’s value, dimensions and weight. The loading and unloading process. Required equipment. And pick-up and delivery locations.

- Know the best flatbed trailer type to use. Some cargo requires specific flatbed types for proper, safe, and legal transport. Determine the right flatbed truck for particular loads to ensure the vehicle meets shipment requirements.

- Leverage freight technology. On top of using truck tracking tools to provide superior customer support, use freight technology to make it easier for your clients to avail of your flatbed shipping services. The latter allows you to provide an online portal that lets customers easily learn and book your flatbed shipping services.

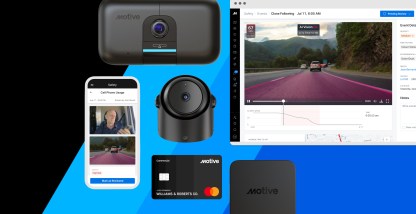

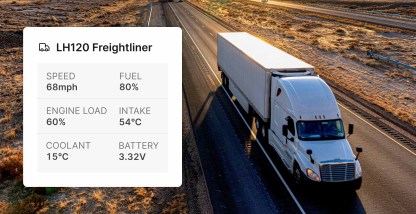

How Motive assists flatbed hauling

Motive offers the technology and tools to simplify and streamline flatbed hauling operations.

Motive’s all-in-one solution includes key functionalities, such as

- Driver safety features, including an Artificial Intelligence (AI) Dashcam that can detect unsafe driving and stop crashes before they occur

- A real-time Global Positioning System or GPS tracking feature to gain overall visibility and monitor your flatbed trucks at all times

- Electronic logging device or ELD compliance technology to simplify and speed up compliance management for your drivers and back-office workers

Ready to access powerful insights for efficient, safe, and affordable flatbed hauling processes? Try a Motive demo today.