A Driver Vehicle Inspection Report, or DVIR, confirms drivers have inspected their commercial motor vehicles before heading out on the road and again at the end of the day. The federal government requires drivers to formally record these pre- and post-trip inspections to help ensure that vehicle issues are identified and addressed. Completing DVIRs is vital for safety and compliance. Having an inspection process can also add fleet savings.

What you need to know about DVIRs

Commercial motor vehicle (CMV) drivers are federally mandated to document their pre- and post-trip vehicle checks on a DVIR form. The requirements vary for the type of inspection, yet the overarching goal is to identify and record any vehicle defects. The process supports safety for drivers, their vehicles, and others on the road.

Legal requirements and regulations

The Federal Motor Carrier Safety Administration (FMCSA), under the Department of Transportation (DoT) regulates pre-trip, post-trip, and periodic inspections. Fleet drivers need to know the requirements for each type of vehicle inspection.

Pre-trip inspection

The FMCSA’s Federal Law 49 CFR 396.13 requires pre-trip examinations. Drivers must thoroughly examine the commercial vehicle’s components and systems before every trip. Checking the fuel tank, vehicle lights, tires, and other essentials before a daily haul helps ensure that the vehicle is safe to drive and in good condition.

Drivers taking multi-day trips would perform a pre-trip inspection every day to remain road safe and compliant. Non-compliance with the Department of Transport (DoT) pre-trip inspection requirements can mean hefty fines and lead to certification and license loss.

Post-trip inspection

FMCSA Federal Law 49 CFR 396.11 requires drivers to perform a post-trip inspection of commercial vehicles at the end of the workday. Drivers operating more than one vehicle must complete separate DVIRs for each CMV.

The post-trip inspection is an opportunity to identify vehicle defects that may have occurred during a trip. Any issues or defects found get reported to the fleet manager or motor carrier to ensure necessary repairs are made before the vehicle is put in service again. This helps minimize future delays that could seriously impact delivery times and operations. These reports can also help fleet managers better understand vehicle health and how different drivers operate their vehicles.

Motor carriers must also maintain the original DVIR, certification of repairs, and certification of the driver’s review for three months from the date of the initial report.

Periodic inspection

All CMVs must also undergo periodic inspection at least once in a 12-month period, per FMCSA Federal Law 49 CFR 396.17, 396.21. Motor carriers must also retain the periodic inspection report for 14 months while keeping documentation of the most recent periodic inspection (sticker, report, or decal) on the vehicle.

Types of DVIRs

Drivers can complete DVIRs manually or electronically. Filling out a DVIR form manually, however, may be more time-consuming. Writing on paper can also require drivers to capture a lot of information in small spaces, which can undermine legibility. Additionally, drivers need to keep track of that paperwork and turn it in. Fleet managers must also monitor, manage, and store many different drivers’ paper forms (with many inspections done per day).

Electronic DVIRs, or eDVIRs make the process more efficient. Drivers can simply log into an app, enter their vehicle/trailer details, select defects from a list, and sign. It’s even easier if you’re using an electronic logging device (ELD) with vehicle inspection functionalities.

Note: The DVIR regulation exempts driveaway-towaway, motor carriers with only one CMV, and private motor carriers that carry passengers but not as a business.

Identifying and documenting vehicle defects

Knowing a DVIR’s meaning helps drivers understand that the purpose of these inspections is to identify and report any defects or maintenance issues. The aim is to ensure that vehicles are safe to operate. This makes it critical for drivers to be thorough and observant during their inspections. Looking for signs of wear and tear, leaks, loose or damaged parts, or any other abnormalities that could indicate a problem with the vehicle can protect drivers, assets, and others on the road.

Pay attention to both the exterior and interior of the vehicle. Document any defects or issues found. This typically involves noting the nature of the defect, its location on the vehicle, and any additional details that may be relevant. Using clear and specific language to describe the problem, and including a rating of the severity, can help fleet managers make decisions about next steps.

Now that we’ve discussed what a DVIR is, the basic legal requirements for the types of inspections, and identifying and documenting vehicle defects, let’s discuss the benefits of instilling basic inspection processes.

Benefits of DVIRs

DVIRs offer several advantages in addition to enhancing safety on the roads. The required periodic, pre- and post-trip inspections simplify early detection and prevention of issues. With drivers documenting any concerns at the end of the day, perhaps even photographing concerns, it’s easier to maintain vehicles before heavy-duty repairs are needed. This is often referred to as preventive maintenance.

Preventive maintenance can offer cost savings by:

- Reducing unexpected downtime

- Optimizing vehicle performance

- Extending asset lifespan

- Maximizing productivity

- Avoiding large-scale repairs

At the same time, with a vehicle inspection process in place, fleets can avoid costly compliance issues. Violations of DVIR regulations could lead to penalties such as

- $1,270 a day for failing to complete a DVIR

- Up to $12,695 for knowingly falsifying, destroying, or changing DVIR records

- Up to $15,419 for each non-recordkeeping violation

Completing inspections for DVIRs makes fleet vehicles more likely to pass any roadside inspections. Otherwise, if a vehicle is deemed unsafe, the truck will be put out of commission for repairs. That can mean downtime, which affects revenue, and lower CSA scores, which can cause a loss of business.

4 DVIR best practices

Along with following fleet management best practices, it is helpful to also focus specifically on inspection strategies for success. These four best practices can support safety, savings, and compliance.

1. Establish a standardized process

Ensure that drivers can complete a DVIR following a consistent process:

- Inspect vehicle interior and exterior, thoroughly.

- After completing the inspection, document any defects or issues.

- Follow the reporting process. This may mean labeling the severity of defects or issues and notifying a supervisor of severe issues. Or the inspection report might go to a specific department if there are no repairs to initiate after that inspection.

- Take corrective action. If defects are reported, appropriate action must be taken to address them promptly. This may involve scheduling repairs, replacing faulty parts, or conducting further investigations to determine the root cause of the defect.

These are the basic steps in a DVIR process, but each fleet may want to customize its vehicle inspection form to address specific business needs.

2. Train drivers on procedures and expectations

When onboarding drivers, make sure that training addresses what needs to be inspected before and after each trip. Also, educate your drivers about the DVIR process and its importance. Emphasizing the safety benefits as well as productivity gains can help motivate drivers to be thorough and observant.

Plan to go over how to complete a DVIR form, whether manually or electronically, and what happens next as far as submitting the records. Remind drivers that retention of records is an essential component of compliance.

3. Use technology for efficient DVIR management

Streamline the vehicle inspection process while improving accuracy by using technology to manage reporting. Options include:

- DVIR app. Mobile apps enable drivers to conduct inspections using their smartphones or tablets, eliminating the need for paper forms. They can also capture images, record audio, and input data directly into digital forms, making the process more efficient and reducing the chances of errors.

- Electronic logging devices (ELDs). ELDs connected to the vehicle’s engine automatically record data related to the vehicle’s operation. Many modern ELD systems let drivers complete and submit DVIRs electronically through the ELD, which simplifies the process and ensures accurate and timely reporting.

- Fleet management system integration. Integrating a DVIR management system with existing fleet management software enables seamless data transfer and consolidation, allowing for comprehensive reporting and analysis. Leverage the technology to automate reminders and notifications for DVIR completion. Connecting inspection reports to maintenance workflow can also streamline work order generation, repair scheduling, and issue resolution.

4. Review and analyze DVIR data

Keeping records of completed inspection reports, repair orders, and maintenance records is required by law. A fleet could need this documentation for audits or compliance checks.

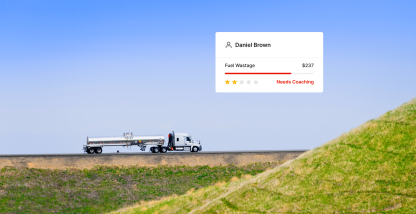

These records also reflect a history of vehicle maintenance. That means these records can provide valuable data for fleet managers looking to better understand vehicle lifespan or maintenance trends. Analyzing the DVIR data can also help to identify and reward drivers who drive their vehicles more carefully.

Electronic DVIR

An eDVIR lets drivers record, compile, and store inspection information on electronic devices such as computers, smartphones, and tablets. The eDVIR data can sync directly to fleet management software through a mobile application to allow for quick, easy, and secure information transfers among stakeholders such as drivers, fleet managers, and trucking company owners.

eDVIRs offer several benefits:

- Save time conducting vehicle inspections

- Ability to take photos of issues for supervisor review

- Reduce paperwork and keep reports easy to read

- Review and update eDVIRs anywhere and in real time

- Enable a proactive approach to issues or defects identified in vehicle inspections

- Increase data visibility with efficient, immediate access to all inspection reports in the system

Customize and track DVIRs with Motive

Drivers can use the Motive Driver App for Android or iPhone/iPad to create electronic DVIRs. Plus, fleet managers can customize DVIRs so drivers assess vehicle parts against a built-in checklist in the Motive Driver App, indicate the severity of the issue, and upload photos.

Motive’s system also alerts managers in real time if drivers report any defects. Then, easily search for DVIRs by driver or vehicle to determine next steps. Managers can also mark defects “corrected” or “need not be corrected” and add a mechanic signature if necessary — all from the Motive Dashboard.

Integrating eDVIRs with Motive’s best-in-class fleet management software also provides advanced reporting to help managers analyze fleet vehicles’ health and maintenance trends to ensure smooth fleet operations. See the safety, savings, and compliance gains firsthand. Request a free demo.